Typical Applications

Thin Film & Coating Systems

Used to monitor chamber vacuum during deposition and coating processes.

Supports stable vacuum feedback for process control.

Ideal for industrial coating equipment.

High Vacuum Research Systems

Applied in physics and material science research setups.

Reliable monitoring in high vacuum regimes beyond Pirani capabilities.

OEM High Vacuum Equipment

Designed for embedded integration into vacuum systems.

PTR225N-compatible signal output simplifies system replacement and upgrades.

Industrial Vacuum Monitoring

Continuous monitoring of high vacuum conditions.

Suitable for long operational cycles in industrial environments.

Suitable / Not Suitable

Suitable for

Not recommended for

Technical Overview

Measurement & Performance

- Measurement principle: Cold cathode ionization

- Measurement range (air): 1×10⁻⁷ to 1×10⁻³ Torr

- Accuracy (air):

- ±20% (1×10⁻⁶ to 1×10⁻³ Torr)

- ±30% (1×10⁻⁷ to 1×10⁻⁶ Torr)

Electrical & Mechanical

- Output signal: Analog voltage, 0–10 V

- Output scaling: Logarithmic, 1.33 V / decade

- Supply voltage: 20–28 V DC

- Power consumption: < 7 W

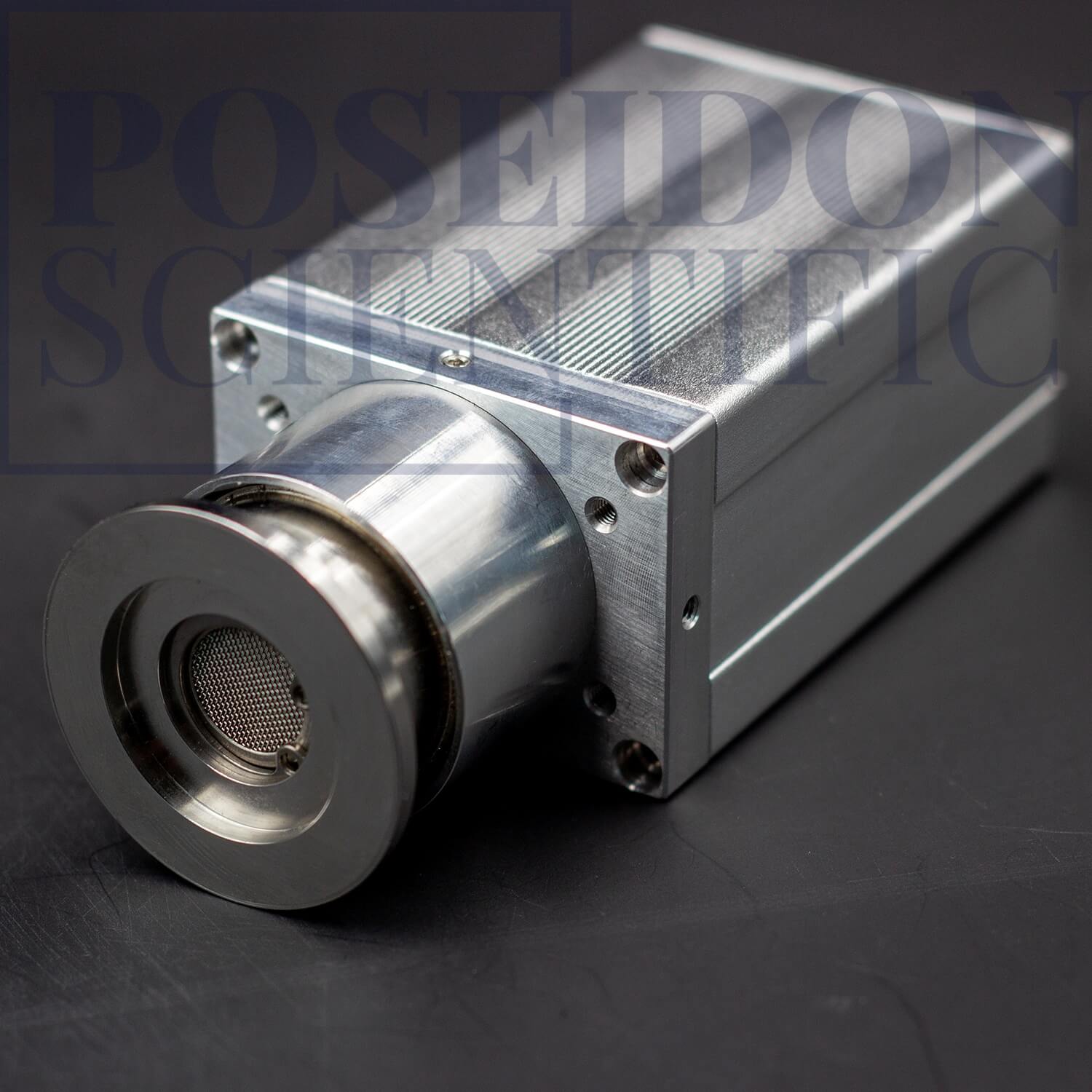

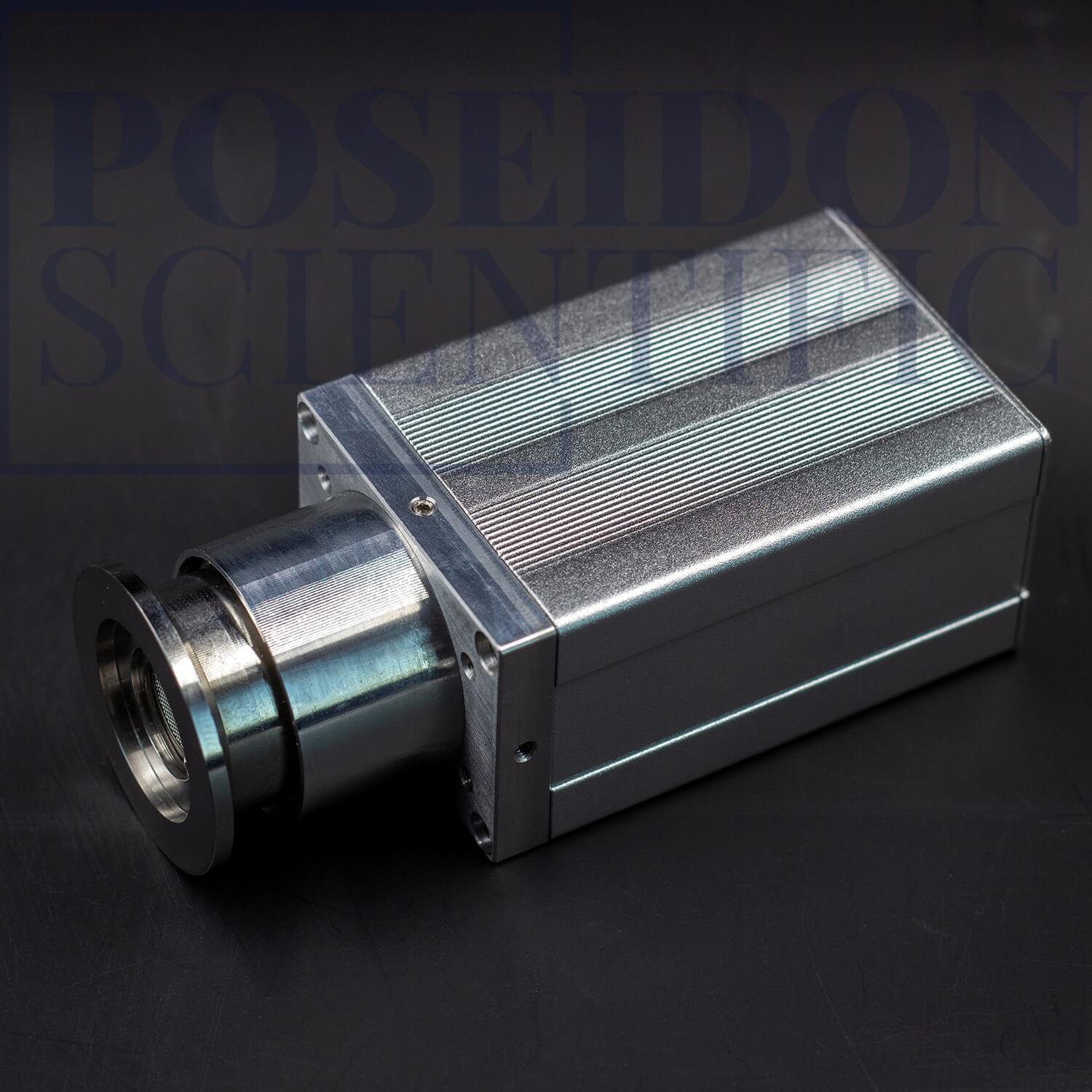

- Vacuum connection: KF25

- Electrical connector: RJ45

Environmental

- Operating temperature: 5–50 °C

Ignition Behavior

Typical Ignition Time (Air)

- At 1×10⁻⁴ Torr: ~2 seconds

- At 1×10⁻⁵ Torr: ~1 minute

- At 1×10⁻⁶ Torr: ~5 minutes

This behavior is typical for cold cathode gauges and should be considered during system startup and control logic design.

Why Choose Poseidon Scientific

OEM & Customization Capabilities

Our engineering team supports small to mid-volume OEM orders with short lead times and technical cooperation.

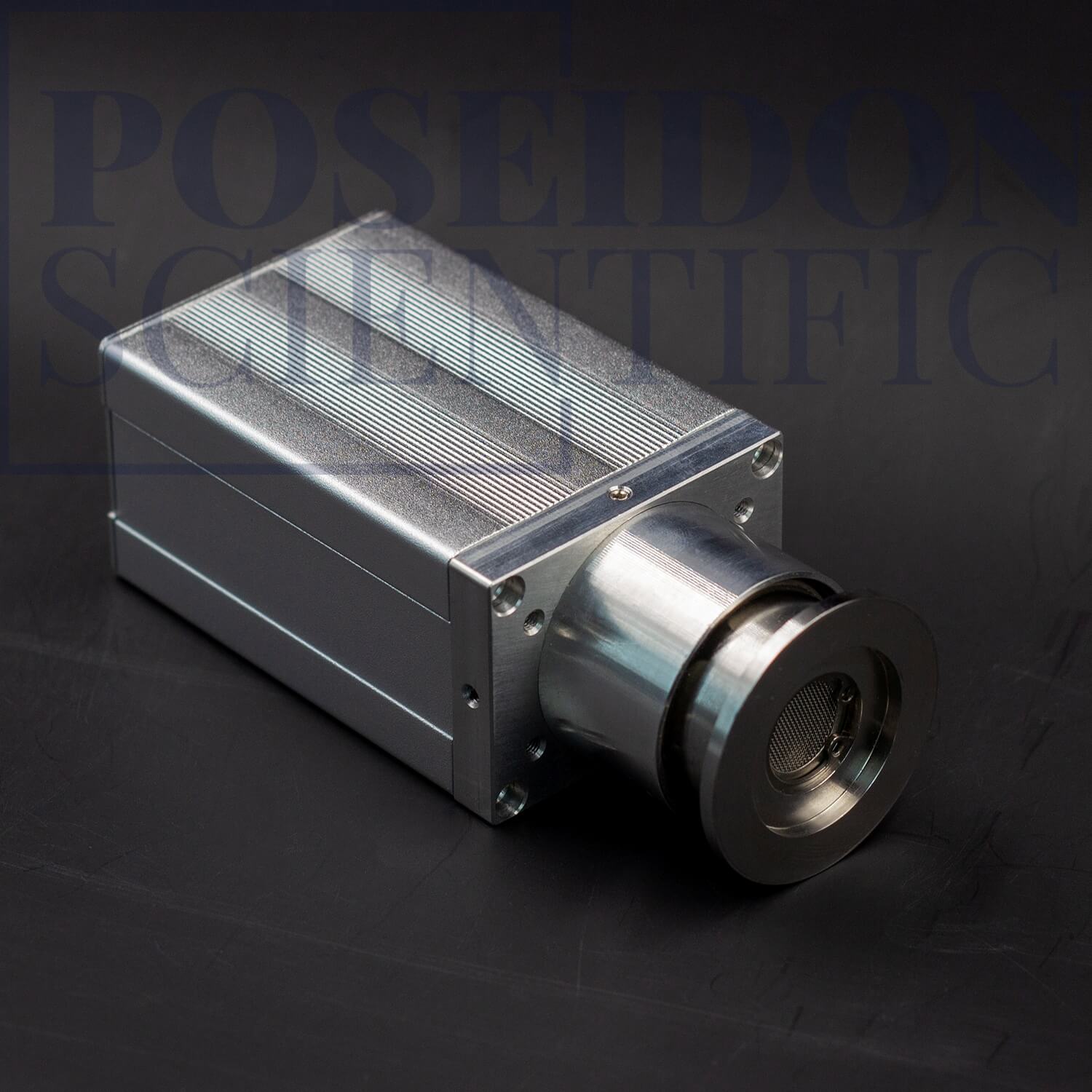

3D preview

Whether you are replacing an existing cold cathode gauge

or designing a new high vacuum system, we are ready to support you.

Talk to Our Vacuum Measurement Engineers

Whether you are replacing an existing cold cathode gauge

or designing a new high vacuum system, we are ready to support you.

Reviews

There are no reviews yet.