When designing or operating a vacuum system, selecting the right pressure measurement device is critical for process stability, safety, and automation.

Two terms are frequently encountered—and often confused: Vacuum Gauge and Vacuum Transmitter.

Although they are closely related, they serve different functional roles in modern vacuum systems. This article provides a detailed, application-oriented comparison to help engineers, system integrators, and laboratory users make the correct selection.

1. Definitions: What Is a Vacuum Gauge vs. a Vacuum Transmitter?

Vacuum Gauge

A vacuum gauge is primarily a measurement device. Its core function is to sense vacuum pressure and provide a readable output—either locally (display) or electrically.

Typical characteristics:

- Focused on pressure sensing

- May provide local indication

- Output can be analog or digital

- Often used for monitoring and diagnostics

Examples:

- Pirani gauges

- Cold cathode (Penning) gauges

- Capacitance manometers

Vacuum Transmitter

A vacuum transmitter goes one step further. It is designed not only to measure vacuum but also to transmit standardized signals to external systems such as PLCs, DCS, or industrial controllers.

Typical characteristics:

- Integrated signal conditioning

- Standardized outputs (e.g. 0–10 V, 4–20 mA, RS232/RS485)

- Optimized for automation and control

- Often compact, rugged, and maintenance-friendly

In practice, many modern products are technically “gauges” but functionally transmitters due to their integrated electronics.

2. Core Differences at a Glance

| Aspect | Vacuum Gauge | Vacuum Transmitter |

|---|---|---|

| Primary role | Measurement & indication | Measurement + signal transmission |

| Output | Local display or raw signal | Conditioned, standardized output |

| Automation readiness | Limited | High |

| Integration with PLC | Indirect | Direct |

| Typical use | Lab monitoring, service | Process control, OEM systems |

3. Measurement Principles and Their Impact on Selection

Understanding measurement principles is more important than the name itself.

Pirani (Thermal Conductivity)

- Working range: Rough to medium vacuum

- Typical range: ~10⁻³ to atmospheric pressure

- Strengths:

- Fast response

- Good repeatability

- Simple operation

- Limitations:

- Gas-type dependent

- Reduced accuracy in high vacuum

Typical applications:

- Vacuum furnaces

- Leak checking

- Load-lock chambers

Cold Cathode (Ionization)

- Working range: High to ultra-high vacuum

- Typical range: ~10⁻⁷ to 10⁻³ Torr

- Strengths:

- No hot filament

- Long lifetime

- Suitable for harsh environments

- Limitations:

- Ignition delay at very low pressures

- Sensitive to contamination

Typical applications:

- High-vacuum coating systems

- Semiconductor tools

- Scientific research chambers

4. Application-Based Selection Guide

Laboratory & R&D Systems

Key priorities: accuracy, stability, flexibility

Recommended approach:

- Use vacuum gauges with clear physical principles

- Local indication is often sufficient

- Digital interfaces preferred for data logging

Example:

- Pirani gauge for roughing stage

- Cold cathode gauge for high-vacuum regime

Industrial Automation & OEM Equipment

Key priorities: reliability, signal compatibility, scalability

Recommended approach:

- Choose vacuum transmitters

- Standard outputs (0–10 V, 4–20 mA, RS232)

- Compact form factor for panel or tool integration

Example:

- Pirani vacuum transmitter for pump-down control

- Cold cathode vacuum transmitter for interlock and process qualification

Multi-Stage Vacuum Systems

In systems covering a wide pressure range, combination solutions are common:

- Pirani transmitter for rough vacuum

- Cold cathode transmitter activated automatically at lower pressure

- Output signals integrated into a single control logic

This architecture improves:

- Measurement continuity

- System safety

- Process repeatability

5. Key Selection Considerations (Beyond Pressure Range)

When choosing between a vacuum gauge and a vacuum transmitter, engineers should evaluate:

✔ Output Requirements

- Do you need analog control signals or just a reading?

- Is the system PLC-based?

✔ Gas Composition

- Thermal gauges are gas-dependent

- Ionization gauges are less sensitive but still affected by contamination

✔ Environment

- Magnetic fields (important for cold cathode gauges)

- Temperature and vibration

- Clean vs. process gas environments

✔ Maintenance Strategy

- Filament-free designs reduce downtime

- Ease of cleaning and recalibration matters in production tools

6. Common Misconceptions

“A vacuum transmitter is more accurate than a vacuum gauge.”

→ Accuracy depends on measurement principle, not naming.

“Vacuum gauges cannot be used in automation.”

→ Many modern gauges include transmitter-level electronics.

“One gauge can cover all vacuum ranges.”

→ No single technology covers rough to ultra-high vacuum optimally.

7. Final Thoughts

The choice between a vacuum gauge and a vacuum transmitter is not about superiority—it is about application context.

- If you need monitoring and diagnostics, a vacuum gauge may be sufficient.

- If you need process control, automation, and system integration, a vacuum transmitter is the better choice.

Understanding your pressure range, control architecture, and operating environment is the key to making the right decision.

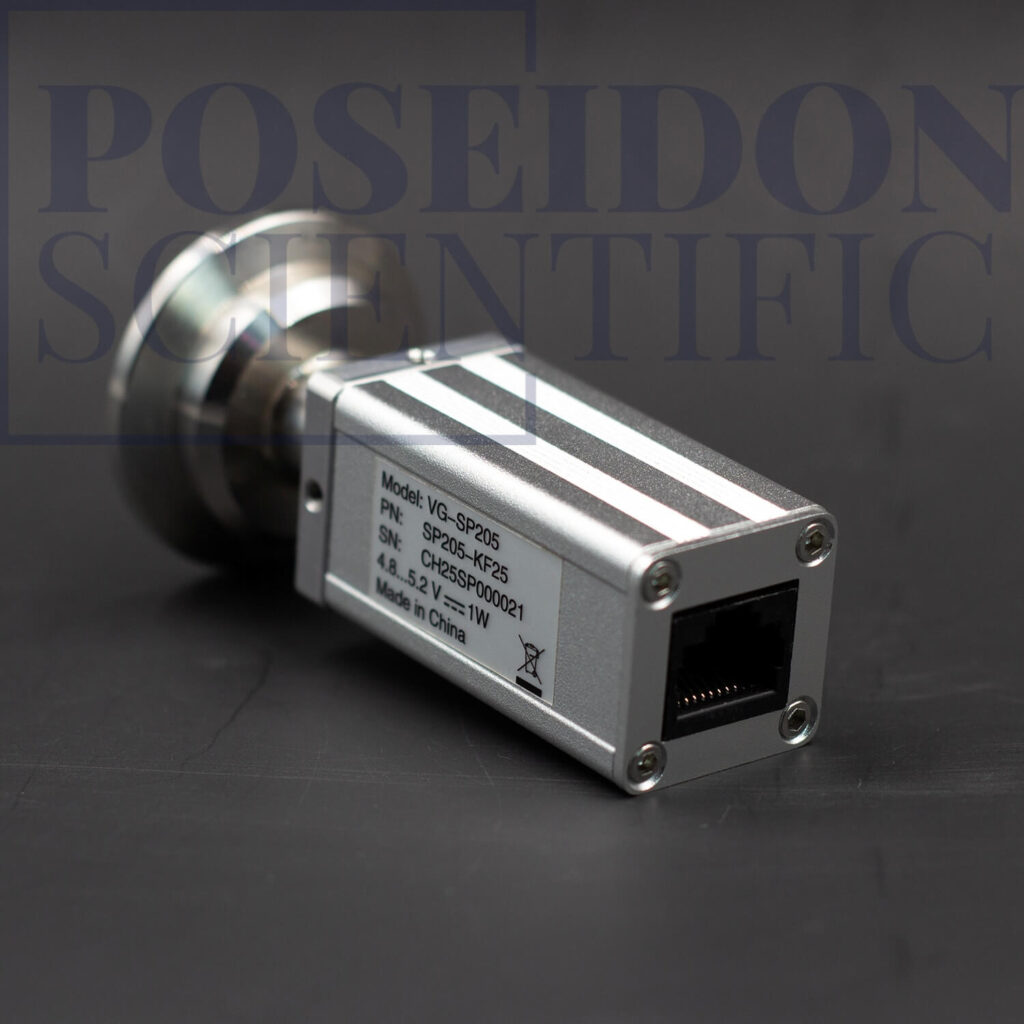

Explore Professional Vacuum Measurement Solutions

Poseidon Scientific offers a complete range of Pirani and Cold Cathode Vacuum Transmitters designed for laboratory, industrial, and OEM applications.

Learn more on our Vacuum Transmitter product pages.